Airport Frankfurt

Frankfurt am Main

- Manufacturers

- TTC Timmler Technology GmbH

- Location

- Frankfurt am Main

- Architect

- gmp · Architekten von Gerkan, Marg und Partner, Hamburg

Reaching for the sky

Transparent and flooded with light, that is how Gate A-Plus at Frankfurt Airport presents itself. This extension was designed by the Hamburg firm of architects gmp (von Gerkan, Marg and partner): The planers focussed on a virtually full glass façade towards the south and the runway and spanned the rotunda in the business area with a glass dome. Even the areas where escalators connect the various floor levels give a taste of the sky. They too have transparent, slightly doomed glass roofs.

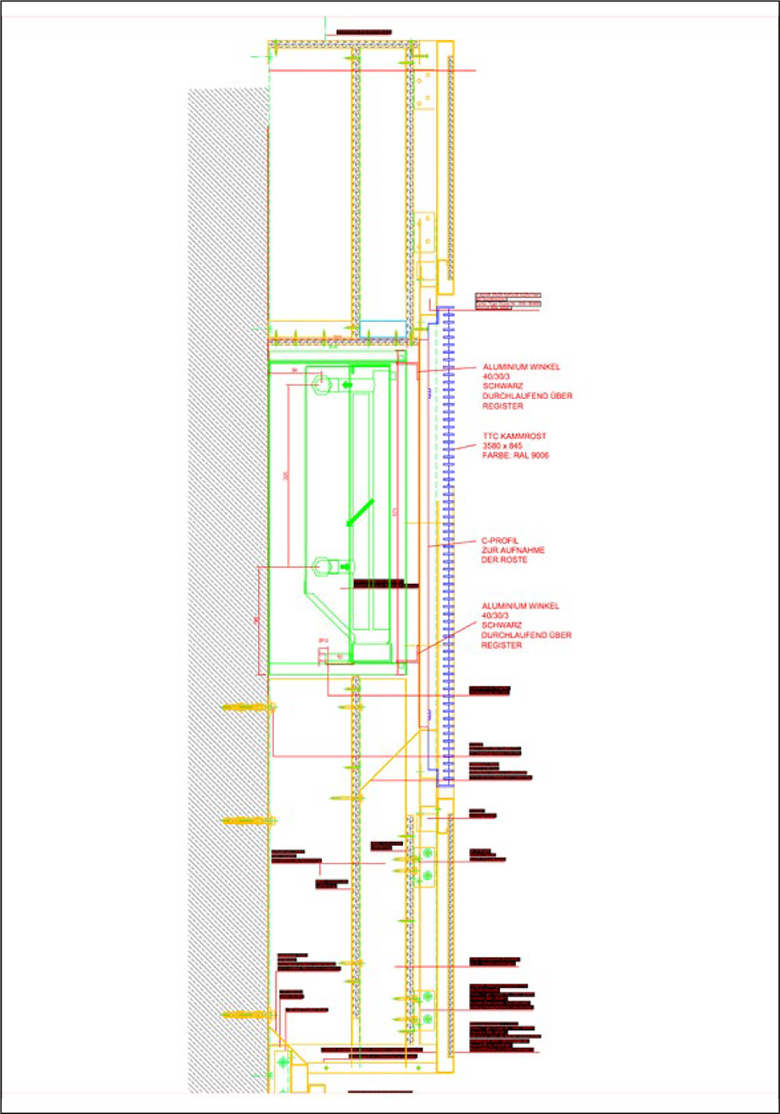

Intelligent heating and air-conditioning technology is needed to give these sections of the building a pleasant indoor climate for travellers from all over the world. Having a glass roof means solar radiation in summer and thus increased temperatures. In winter, however, the entry to the escalator area can cool down considerably. Considering the additional capacity of six million passengers per year this presents a major challenge for the air-conditioning technology. TTC Timmler Technology, as a specialist for state-of-the-art energy efficient systems, has contributed an innovative solution that matches the concept of the high-quality interior design: 28 heating and cooling ducts are positioned behind the wall panelling, invisible to the eye of the observer.

The gravity cooling in particular is very energy-efficient because warm air that rises upwards is sucked in through discreet openings and then cooled with water. It then re-enters the room as a refreshing breeze through gratings at the foot of the wall. This process has numerous advantages: The water cooled GraviVent system entails significantly lower costs than traditional applications. It operates in silence and the low-impulse displacement ventilation is very unobtrusive. Convector heaters guarantee a comfortable room climate during the winter months. The air-conditioning operates gently and evenly – both cool and warm airflows disperse imperceptibly.

The covers at the upper end of the wall panelling and in the floor also come from TTC Timmler Technology. The substructure for the gratings was produced in close cooperation with the drywall constructor and the specialist firm for ceiling and wall systems and the length of the comb gratings was adapted to the panel dimensions. Hence, joint matches joint, resulting in homogenous surfaces.

GraviVent® | Technical Specification

GraviVent cooling units type ASIS 51.21.2

→ Performance: high power capacity category 2 with condensation tray and drain pipe Front side powder-coated black

→ 30 units 1,800mm

→ 5 units 2,400mm

Heating convectors type HK 2.075.200

→ made of copper pipes with aluminium fins

→ 22 units 1,800mm

→ 5 units 2,400mm

Air inlet at the top

Linear gratings type KST 18.03.77 AP

→ made of aluminium, bar distance 10 mm, total height 45 mm, powder-coated according to RAL 9006

→ 22 units 3,600 x 845mm [L x W]

→ 4 units custom-made fitting pieces

→ 6 units 2,700 x 845mm [L x W]

Air outlet at the top

Linear gratings type KST 18.03.77AP

→ made of aluminium, bar distance 10mm, total height 45mm, powder-coated according to RAL 9006

→ 22 units 3,600 x 270mm [L x W]

→ 4 units custom-made fitting pieces

→ 6 units 2,700 x 270mm [L x W]

Related Projects

Magazine

-

Von »Stadtlagune« bis »LandArtPark«

1 day ago

-

Naherholung am Wasser ermöglichen

2 days ago

-

Strahlen für Sichtbarkeit

2 days ago

-

Wo wirtschaftlich umweltfreundlich bedeutet

3 days ago